COMBY

DENTAL LAB FURNITURE

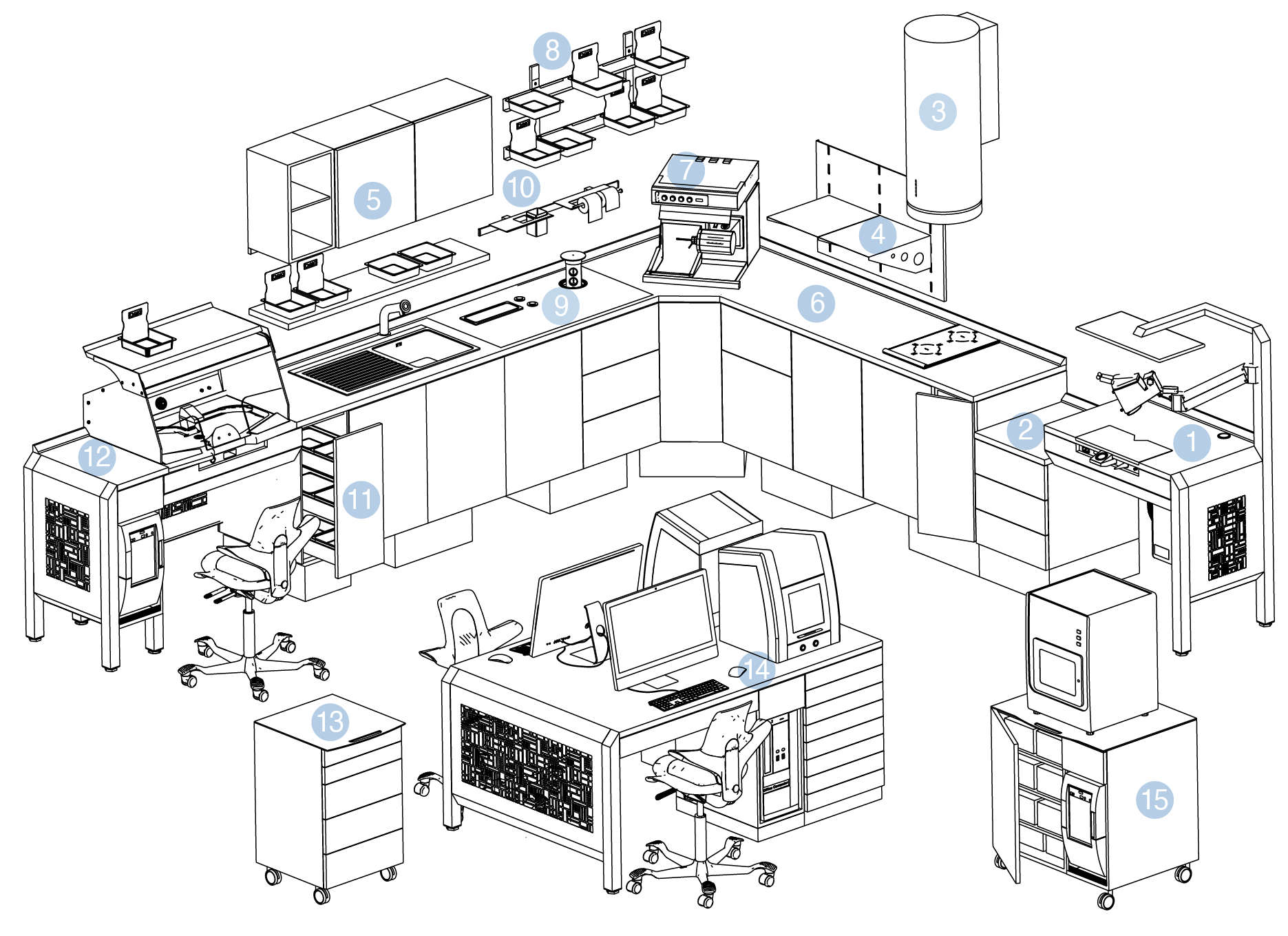

Reinterpreting tradition to create a line with a young and versatile spirit, the origin of a complex interplay between simplicity and concreteness. The harmony of colours and finishes marry functionality and modularity in Comby, creating a new way of conceiving the working space.

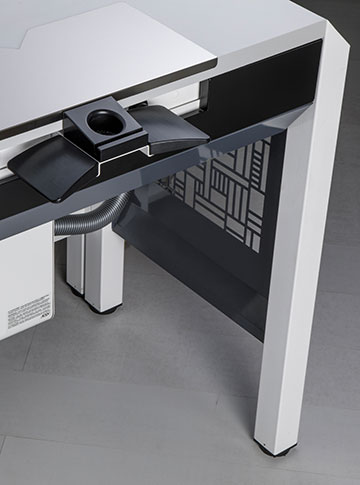

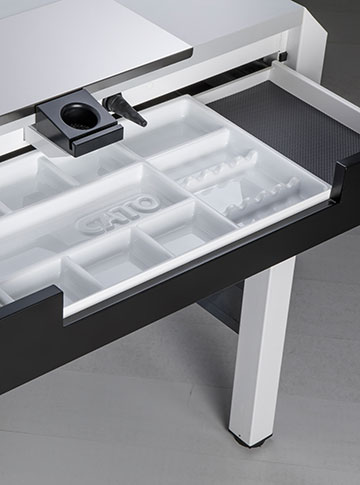

Download:A work space that favors organization and cleaning thanks to the reallocation of the electro pneumatic systems under the worktop, the internal application of the rotating instrumentation into the drawers and the elimination of the handles from the drawer fronts.

1 Turbine/electric spatula support

2 Micromotor support

3 Cable hole cover

4 Multi-function shelf

5 Backsplash

6 Lamp switch

7 Sb steel protection

8 Aspiration control buttons

9 Aspiration point

10 Sliding support point

11 Air bellows housing

12 Pressure reducer for turbine

13 Instruments container

14 Material/tools housing

15 Milling tools housing

16 Steel dirt container

17 Drawer with integrated handle

18 Rotating instruments housing

19 Antitrauma drawer front

20 Customizable panels

21 Customizable panels

22 Aspiration system

23 Underfloor Schuko socket 220V

24 Knee micromotor activation

25 Push and pull opening

26 Support element

27 Adjustable leveling feet

Custom-made is one of our main strengths and, thanks to a flexible and dynamic vision of the environments, has allowed the development of modular lines for modular solutions according to the different structural and functional requirements.

1 Workstation

2 Lowered module

3 Hood module

4 Hanging modules

5 Hanging modules

6 Service modules

7 Polishing unit

8 Work boxes grid

9 Plaster module

10 Accessorised shelves

11 Work boxes module

12 Finishing module

13 Module on wheels

14 Scanner/CAD station

15 CAM module

Our attention to style allows the customization of the furnishings through the proposal of a wide color scale. All the paints are made with epoxy powders that protect the furnishings from a possible formation of rust. The metal surfaces are lacquered with epoxy powders hot cured 180 °. The polymerized film is 60 microns for glossy surfaces and an average of 70 microns for surfaces witha Bucciat finish.

Bianco 9003

Bianco 9003

Limone 1016

Limone 1016

Arancione 1028

Arancione 1028

Rosso 3028

Rosso 3028

Blu elettrico 5002

Blu elettrico 5002

Verde 6000

Verde 6000

Grigio agata 7044

Grigio agata 7044

Tortora 7036

Tortora 7036

Grigio fumo 7037

Grigio fumo 7037

Grafite 7015

Grafite 7015

Nero 9017

Nero 9017

Albicocca 0408520

Albicocca 0408520

Visone 0407005

Visone 0407005

Caffélatte 0406005

Caffélatte 0406005

Caffè 0205005

Caffè 0205005

Verde acido 1209030

Verde acido 1209030

Verde pastello 1408010

Verde pastello 1408010

Assenzio 1407010

Assenzio 1407010

Salvia 1606010

Salvia 1606010

Muschio 2006010

Muschio 2006010

Petrolio 2205010

Petrolio 2205010

Carta da z. 2607015

Carta da z. 2607015

Blu notte 2605015

Blu notte 2605015

Blu navy 2603025

Blu navy 2603025

Before choosing the ideal material for the different operational worktops, one should ask oneself what are the characteristics of the material that will be most useful to us in the course of daily operations. On the choice of the most suitable top for different needs, certainly weighs the aesthetic component, but this must never ignore the working habits. We provide you below with a brief guide on the characteristics and maintenance necessary for each of the materials we use for the realization of our worktops.

Bianco 751

Bianco 751

Grigio 1366

Grigio 1366

Argilla 1027

Argilla 1027

Fumo 1023

Fumo 1023

Grafite 1397

Grafite 1397

Legno grigio

Legno grigio

Bianco

Bianco

Grigio

Grigio

Fumo

Fumo

Argilla

Argilla

Visone

Visone

Bianco

Bianco

Grigio

Grigio

Argilla

Argilla

Fumo

Fumo

Grafite

Grafite

You might also be interested in:

SHARP

SHARP is the collection characterised by great aesthetic and stylistic cleanliness. An essential design behind which lies an extraordinary wealth of detail, the essence of a development focused on the enhancement of the product and its functional content.

Find more on SHARP